Climate change issues, the increasing rate of global carbon dioxide emissions are pushing governments and the oil & gas sector in search of more efficient, sustainable and less polluting energy production systems.

The EU funded SOLARSCO2OL Project Consortium made up of 14 international partners coordinated by RINA Consulting S.p.A. and located in 6 EU countries (Italy, Spain, Germany, Greece, Belgium, Sweden) and 1 extra-EU country (Morocco).

The main objective of SOLARSCO2OL Project Consortium is to demonstrate an innovative, economically viable and easily replicable sCO2 power block that, also coupled with fast reactive electric heater and efficient heat exchangers (HEXs), will enable the operation and design of a novel integrated power plant layout in order to un-tap Concentrated Solar Power(CSP) plant potential flexibility and reduce their Levelised Cost of Electricity (LCOE) to values below 10 c€/kWh, also promoting an innovative power plant cycle layout not requiring water.

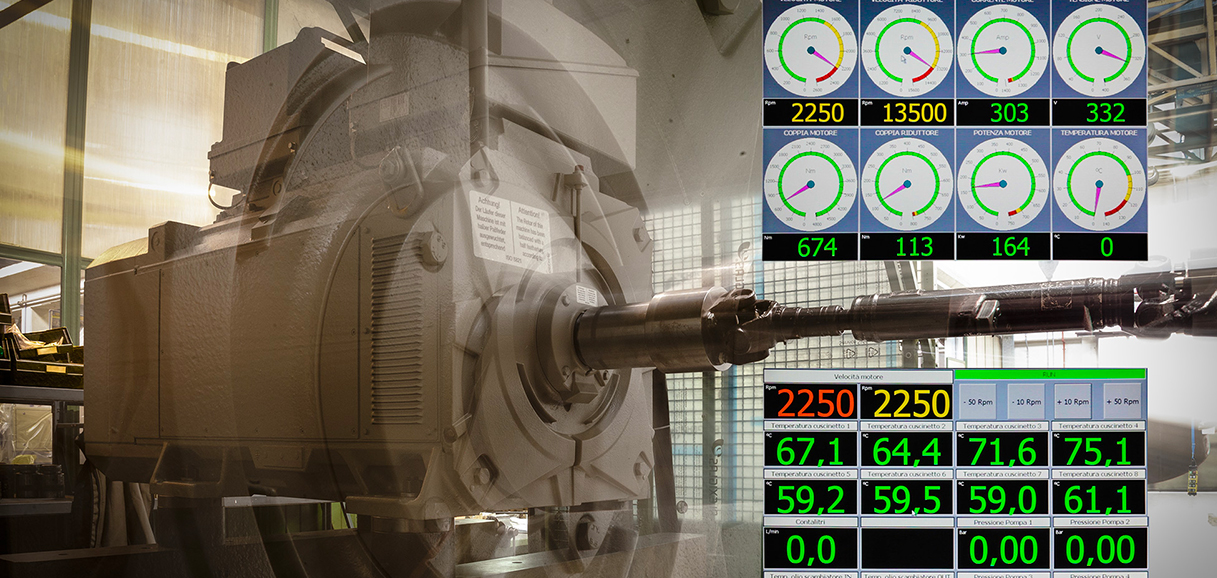

OTG is mainly involved in the optimization and redesign of the classic turbine – reducer – electric generator scheme by introducing the sCO2 turbine into the gearbox casing thanks to the direct connection of the impellers and volutes of the turbine to the shaft and gearbox case.

By 2024, SOLARSCO2OL technological solution will be deployed and demonstrate in a real CSP plant in Spain (La Africana) and studied for replication also in extra-EU countries for example in “Noor III solar tower plant” in Morocco thanks to MASEN support.

The innovative SOLARSCO2OL layouts will enable lower LCOEs, which is in line with SET Plan targets of <10c€/kWh for and it will guarantee short payback periods also by diversifying revenues for plant owners by maximizing the sale of ancillary services.

SOLARSCO2OL has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement n. 952953