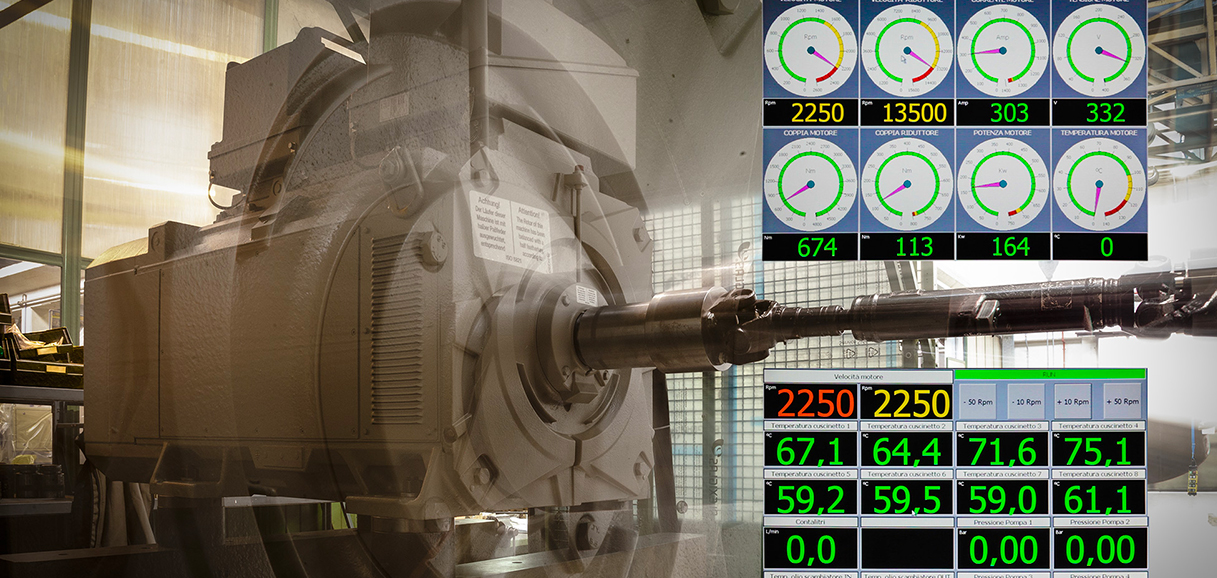

We are proud to announce that the machine test bench has been updated with the installation of a new 750KW motor with 250KW braking power, totally managed by a control system developed entirely within the company.

The control system allows not only the complete management of the engine operating parameters but also the monitoring of all the sensors of the engine, the lubrication pumps and the units to be tested.

The control panel is completely customizable with the values of all the temperature and pressure sensors defined with our customers.

The new devices have also been integrated into the witness machine running test system, improving the user experience for our customers who assist virtually remotely in real-time to all tests and contractual inspections.