BACK

GLASS INSULATORS PRODUCTION LINE

PRODUCTION

SECTOR

TECHNICAL

DOWNLOAD

BROCHURE

CONTACT US

The production process for glass insulators, due to the very delicate function of the articles to be produced, needs the maximum attention to any detail starting from the quality of raw materials, percentage of each component in glass composition, glass temperature in every point of processing line till the storage method and time.

This is the reason why the production process doesn’t terminate with the packing of the products but sophisticated control machines and tests are required before including the item in the final supply. Furthermore the manufacturing is not limited to glass processing but includes also the preparation, control and assembling of cement caps and pins needed to realize the insulator chain for high tension airlines. For these reasons the scope of supply by OCMI-OTG and its partner companies covers a wide range of machinery and specifically the following processes:

For glass shells production:

1. Melting of a batch of suitable composition

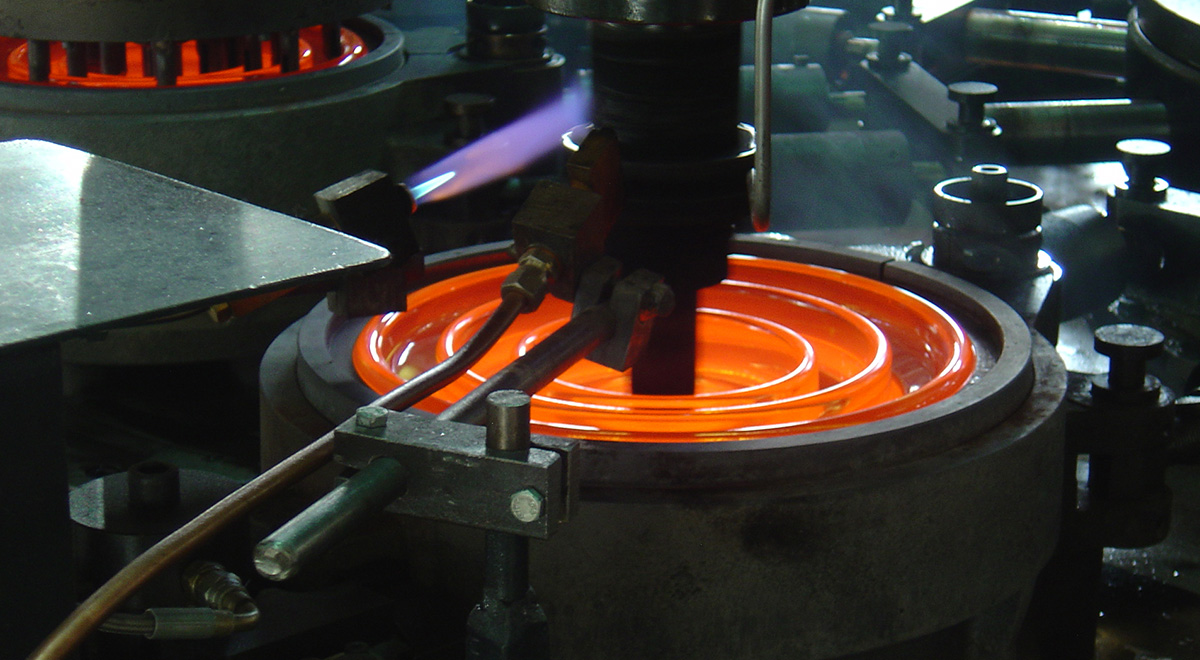

2. Forming by a special press

3. Temperature homogenising.

4. Toughening.

5. Thermal, mechanical and dimensional tests.

For insulators assembly and controls:

1. Assembly with cement and metal fittings.

2. Routine thermal, mechanical and dimensional tests.

For insulators qualification:

1. Type tests and sample tests in accordance with International Standard.

The production line can be purposely developed according to various volumes of glass tons pulled from the melting furnace. The pressing machine supplied by OCMI-OTG performs the forming of glass shell and can be adapted for the production of the different shapes of suspension-type insulators: standard, fog-type, open profile. The shape is given to the glass gob through a multiple rotating plunger with integrated cooling system. The thermal treatment performed through homogenising tunnel, thoughening machine, two annealing lehrs and water bath, allows giving the requested characteristics of mechanical resistance to the finished insulator. This is a really critical passage in this workflow since the insulator will be exposed to any type of environmental conditions and despite of that it must keep its intrinsic characteristics. Temperature changes are purposely applied according to the level of thermo-mechanic resistance requested for the article. Regarding post-production operations, OCMI-OTG can supply the needed know-how for the development of assembly department and test laboratories.