BACK

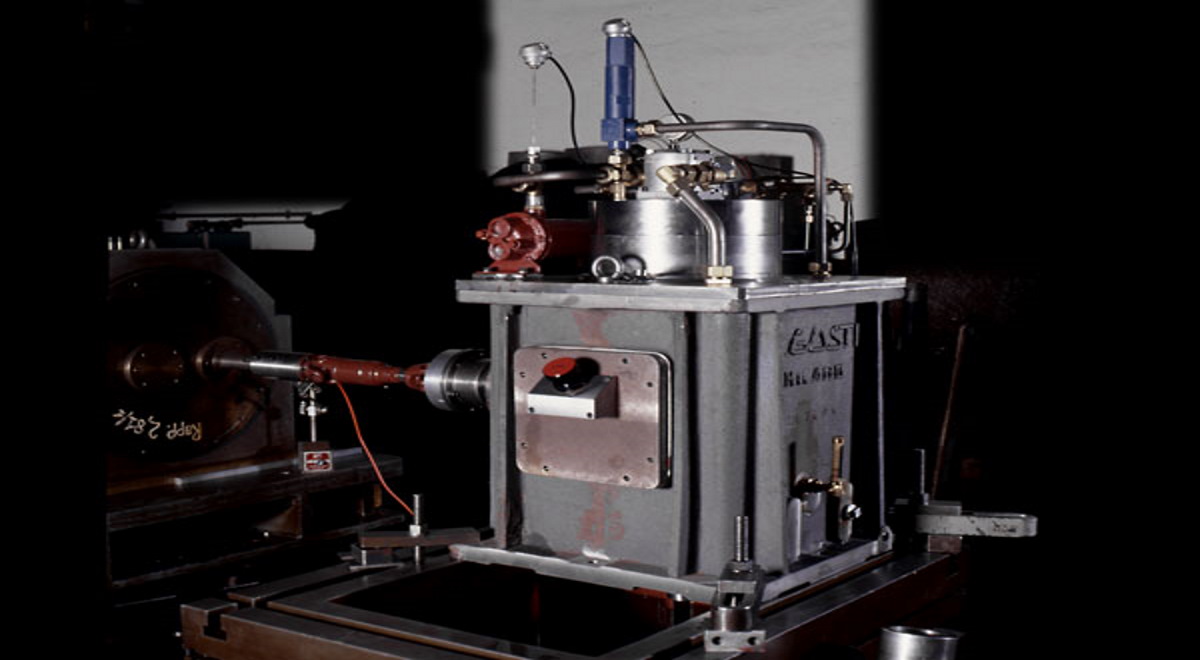

GR SERIES

GR right-angle gears step-up and reduction gearboxes

MAIN TECHNICAL FEATURES

|

Casing in grey cast-iron or welded and annealed carbon steel, complete with inspection window and breather pipe |

|

One pair of bevel gears in forged alloy steel, carburized and hardened, teeth lapped or finished grinding after heat treatment |

|

Both rotors dynamically balanced in accordance with API613 or ISO1940 rules |

|

Bevel rollers or sleeve type bearings |

|

Oil seal labyrinth or retaining ring on high speed shaft |

|

Oil seal retaining ring on low speed shaft |

|

Anti-rotation device fitted on the low speed shaft (free wheel) if required |

|

Forced feed lubrication by means of separate lube oil system |

|

Special models with hollow shaft for fire fighting application as per NFPA-20 notes |

|

Lubrication system available on request |

|

ATEX certificate available on request |

COMPLEMENTARY INSTRUMENTATION

|

Thermoelements on heat exchanger |

POWER

|

From 100Kw to 40000 Kw |