BACK

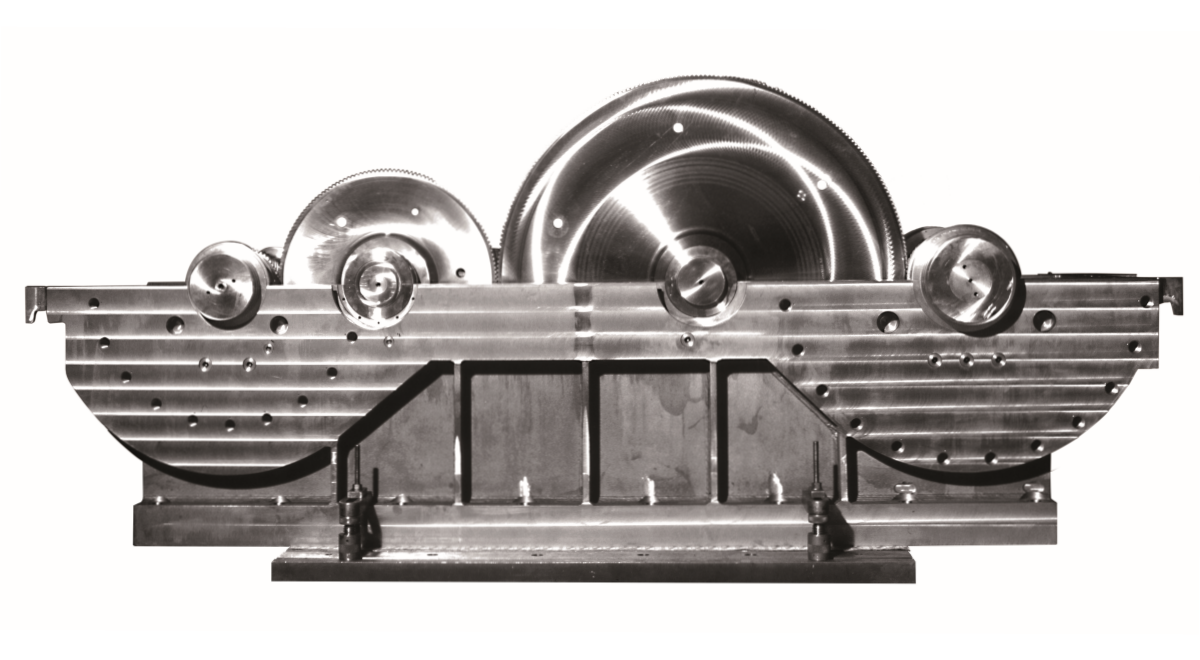

HS Series

HS parallel shaft gears step-up gearboxes for high speed

MAIN TECHNICAL FEATURES

|

API or AGMA calculations |

|

Carter in pre-fabricated steel, welded and het-threated after welding |

|

Single helical gears in forged alloy steel carburized and hardened, finished by grinding after heat treatments, teeth quality as per DIN 5 Class |

|

Low speed shaft in forged alloy steel |

|

Each rotor dynamically balanced in accordance with API613 or ISO1940 specifications |

|

Low speed shaft radial bearing fixed profile type |

|

High speed shaft radial bearings tilting pad type |

|

Axial bearing taper land/tilting pad type on low speed shaft |

|

Thrust collar in 3 pieces on high speed pinion |

|

Forced feed lubrication by means of separate lube oil system |

|

ATEX certificate available on request |

COMPLEMENTARY INSTRUMENTATION

|

Resistance temperature detectors for bearing temperature monitoring |

|

Vibration probes (or preparation of provisions for their installation only) |

POWER

|

From 100Kw to 40000 Kw |