BACK

SA

PRODUCTION

SECTOR

TABLEWARE

DOWNLOAD

BROCHURE

CONTACT US

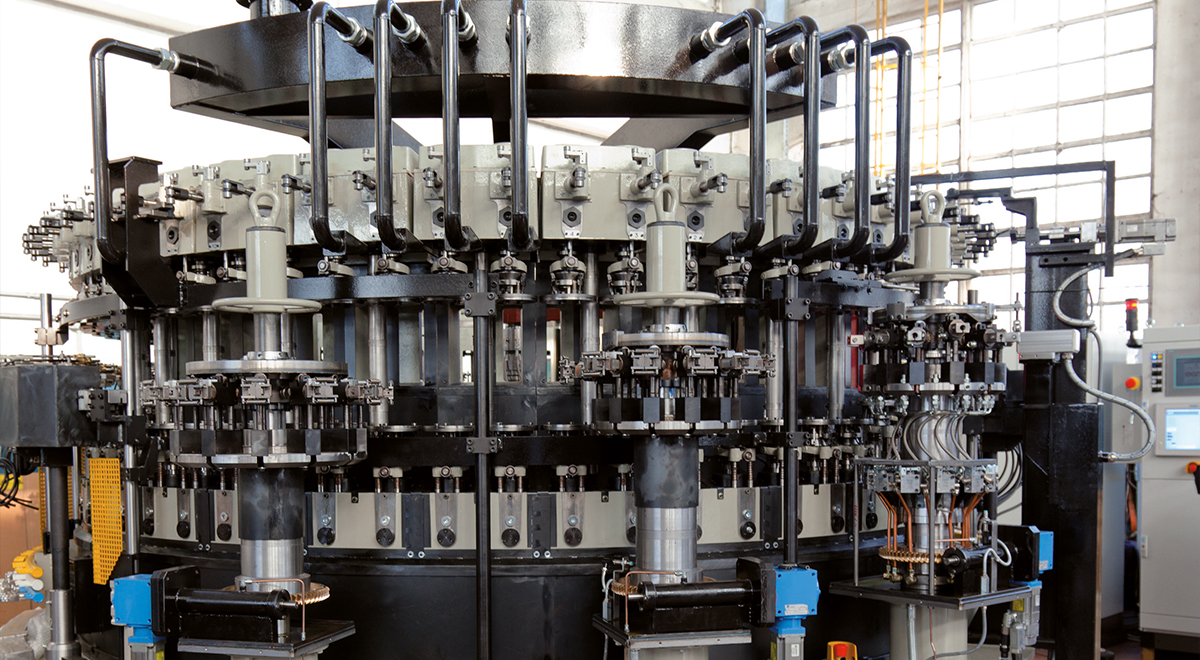

The sealing machine SA, available in the versions with 42, 48 or 60 spindles, allows to join pressed stems and press-blown or blown-blown bowls and manufacture glass stemware. Stretching operation is available on customer’s request. OCMI assures the maximum flexibility of machine layout according to customer’s needs.

The loading area consists of two loading devices for stems and bowls with 12 arms each. Unloading operation of finished articled is made by a third device with 12 arms.

The bowls are loaded in the lower chucks of the machine while the stems go to the upper chucks. The lower/upper chucks can be developed with some adaptations in order to correct any defect in stemware axiality or avoid breakages.

The upper chucks could be automatically adjusted in height through a camera control system checking the level of the items into the machine.

All burners follow with perfect synchronization the movement of articles inside their action range and the nozzles are internally designed and developed by OCMI in accordance with the different operation to be made on glass.

All SA sealing and stretching machines are suitable to work in off-line mode, with items coming from heating tunnels, or in line with pressing and press-blow or blow-blow machines.